Application

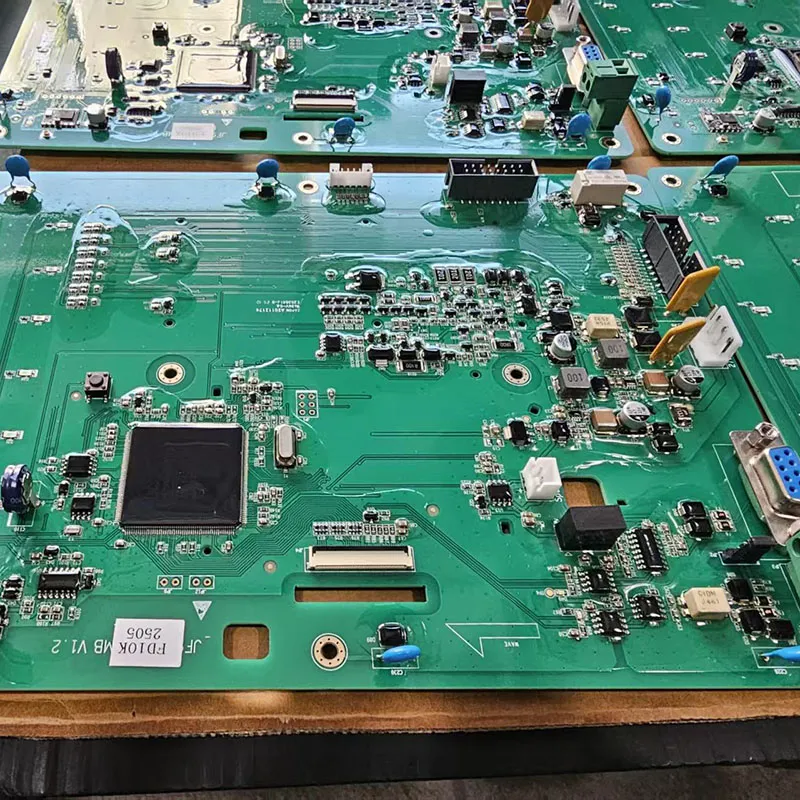

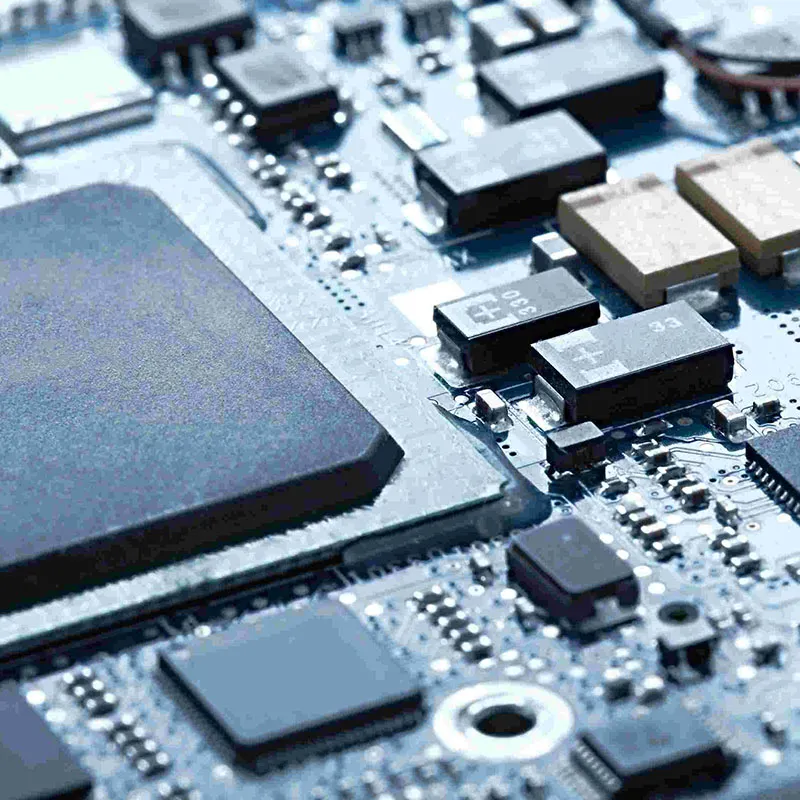

1. Electronic circuit coating protection, waterproof, mildew-proof, corrosion-resistant, and anti-aging.

2. Especially suitable for PCB circuit board coating protection in smart meters, household appliances, and automotive electronics industries.

Feature

• Single component, solvent-free

• Fluorescent, easy to check

• Excellent construction performance

• Excellent salt spray resistance

• Excellent waterproof, moisture-proof and other protective properties

• Good wettability, suitable for PCB boards of different materials

Glue properties before curing:

Base Material | Polyurethane acrylate |

Color | Colorless to light yellow |

Viscosity(mPa.s) | 150 |

Specific gravity (@23℃) | 1.10 |

Surface dry energy (mJ/cm2) | 1000 |

Performance after curing:

Adhesion(Grade) | 0 |

Hardness(Shore A) | 60 |

Tensile Strength(MPa) | 3.57 |

Elongation At Break(%) | 199 |

Volume resistivity (ohm-cm) | 3.7×1014 |

Dielectric constant (1MHz) | 3.2 |

Dielectric strength (KV/mm) | 23 |

Surface resistance (ohm) | 4.3×1014 |

Flame retardant grade (UL 94) | V0 |

Operating temperature (℃) | -60~135 |

Standard conditions: temperature 23±2℃, relative humidity 50±5%RH.

Usage

1. The product is sensitive to light/moisture. It needs to be stored in a dry and airtight environment during storage and operation, and the exposure to various light sources such as sunlight, UV light and other artificial lighting sources should be controlled;

2. It is recommended to clean the surface of the coated product during use to remove surface impurities, oil stains and other pollutants to obtain the expected coating effect; manual brushing, mechanical spraying and other coating methods can be used;

3. If the glue is shaken before construction, it must be left to stand for a period of time until the bubbles disappear before use;

4. Curing: The UV curing rate depends on the intensity, wavelength, coating thickness and distance from the UV lamp to the coating. For areas where UV light cannot reach, the moisture curing mechanism works. Generally, after UV exposure, the surface is dry, and it can be basically dried at room temperature for 3 days. If the final performance is required, it generally takes 7 to 14 days, which also depends on the coating thickness, temperature and humidity of the operating room. The type of light source also affects the curing rate;

5. The uncured adhesive can be removed with appropriate organic solvents such as IPA, MEK, etc.

Precaution

This product is sensitive to light and moisture. During storage and operation, it is necessary to control the exposure to various light sources such as sunlight, UV light and other artificial lighting sources; it is strictly forbidden to expose it to a humid environment, and it should be used up as soon as possible after opening. This product is a safe and non-toxic substance after curing, but it should be avoided from contact with the skin before curing. If it splashes into the eyes accidentally, it should be quickly rinsed with plenty of water.

Safety and Storage

1kg, 5kg. Can be packaged according to customer requirements.

Store in a ventilated and cool place (4~28℃), shelf life of 6 months;